Electrical compliance testing falls into two areas; electrical periodic installation testing (Electrical Installation Condition Report)and portable appliance testing (PAT Testing)

Electrical installation testing involves testing the electrical circuits and systems that distribute electricity around a building. All electrical circuits in a building that are fixed, such as lighting, socket outlets, supplies to air conditioning and other fixed plant supplies need to be tested.

PAT is the systematic checking of any equipment which has a plug. This testing involves visual checks and combined inspection and testing using a PAT test meter. Portable appliances are tested at varying intervals depending on the category they fall into such as stationary , IT , moveable , portable and handheld weather used by the public or in the work place, this varies from 3 months to 48 months.

Electrical Inspection & Testing

GES Ltd offers many types of electrical inspection and testing services as outlined above, although we are a recently formed company we have been in the field of electrical inspections for over 25 years. we are a family run business and as such we value all our clients equally, we have a simple philosophy that :-

‘’YOUR SATISFACTION IS OUR GUARANTEE’’

GES continually maintains a high standard and strives to put itself at the forefront for its exceptional customer care and quality of service.we have a passion for technical excellence and quality to deliver work to the highest standards. Despite many changes in legislation and Health and Safety, we strive to be innovative and flexible with safety at the forefront of all works undertaken.

GES Ltd aims to provide customers with the best possible approach to safety for their employees, possessions and buildings without compromising on the quality of work we undertake. We work closely with our clients to establish their needs before offering a solution

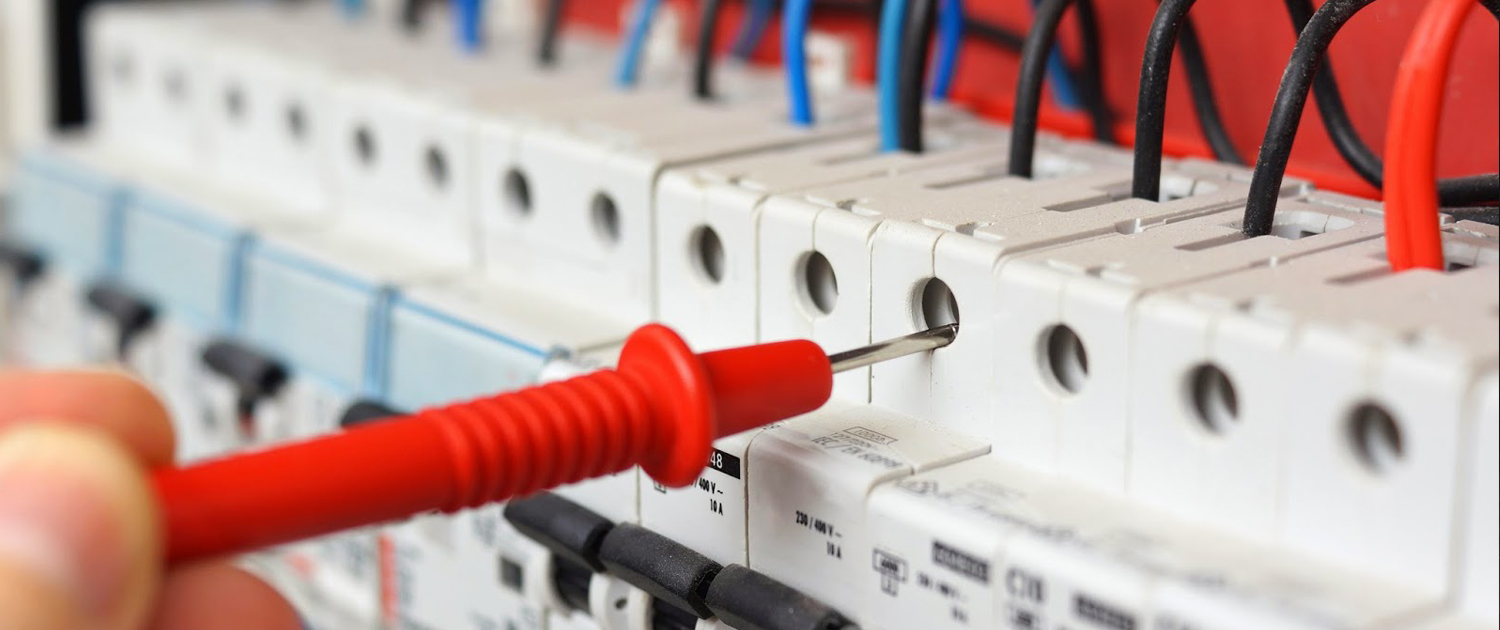

Fixed Wire Testing & Inspection

BS7671 as amended Electrical Installation Condition Report

A fixed electrical installation includes all parts of a distribution system from the main incoming supply point, through to wiring accessories such as sockets and light fittings – and everything in-between.

Because the majority of this part of the installation is unseen, it is often forgotten in terms of test and inspection. The fact is that it is vitally important that all wires, cables, accessories and switching equipment are maintained in a good order to ensure safety.

The process of Fixed Installation Testing, involves ,that a visual inspection is carried out along with various electrical (electronic) tests. Engineers are looking to identify any potentially dangerous defects within the system that may lead to fire or injury.

The benchmark for this inspection and test process is BS 7671 (The IEE Wiring Regulations) which provides guidance on how systems must be designed, installed and maintained. Deviations from this British Standard are most likely to be the cause of any problems.

GES Ltd can also offer our customers a remedial solution to repair any defects found during the test and inspection process.GES Ltd after the inspection and test has been carried out can prepare a no obligation quotation to repair any deviations from BS7671 and provide the required certification in each case.

Remedial Work

Periodic fixed installation testing is only part of electrical safety compliance.Essential remedial work must be completed. This can be:

- Installing labelling

- Replacing broken sockets and switches

- Replace/fix damaged/loose/corroded wiring

- Investigation into poor electrical test readings

- Replacing missing screws

If the essential remedial work is not complete following testing, then the organisation could be liable for fault and negligence.

In a recent survey carried out of over 300 organisations that have had testing done, it was discovered that over half admit that no remedial work has been done subsequent to that testing.

When electrical safety testing is done, any ‘damage, deterioration, defects and dangerous conditions within installation’ will be reported.

These fall into three coded area’s :-

- Code 1- Danger Present – Risk of injury, immediate remedial action required.

- Code 2- Potentially Dangerous – urgent remedial action required

- Code 3- improvement recommended

Any fault reported as code 1 or 2 must be remedied and re-tested to satisfy the original report.

Note: any remedial works carried out include the re-testing and a satisfactory report supplied.

Great for you

This type of work is necessary because all electrical installations deteriorate due to a number of factors such as damage, wear, tear, corrosion, excessive electrical loading, ageing and environmental influences.

Defects in electrical installations can be dangerous. Hence, it is very important to confirm that the installation is not damaged or deteriorated, undertaking regular periodic inspection and performing testings, which will both promote safety and ensure legal compliance. This will protect people from electric shocks, protecting property from damage caused by fire and heat arising from a defect.

GreenTech Electrical Services Ltd cares about your safety and your family wellbeing and we can help you to assure your home or office electrical installations are not damaged or deteriorated. With a team of reliable and qualified electrician, we promote safety and legal compliance.